| 1. Integrated Liquid Storage & Safe Operation

Traditional methods for liquid nitrogen replenishment, such as manual pouring or using pumps, are physically demanding and pose safety risks like container slippage or leaks. For example, pouring liquid nitrogen from a 30L or 50L liquid dewar is difficult and often requires assistance.

In contrast, the liquid nitrogen supply tank integrates both storage and transfer functions, eliminating the need for additional tools. This makes refilling more efficient and safer, while reducing operational risks.

2. Multiple Models Available

To cater to varying usage needs, from high to low consumption, the liquid nitrogen supply tank comes in sizes ranging from 15L to 500L. Custom horizontal models are available for tanks above 500L, making them suitable for both small-scale research and large-scale production.

3. Manual & Automatic Options

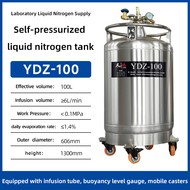

Equipped with a valve, pressure gauge, and liquid level indicator, manual operation is the standard function. Additionally, you can install electromagnetic valves for smart control integration with systems like YDD, CryoBank, or liquid nitrogen cryotherapy units, allowing for automated replenishment.

To ensure consistent nitrogen flow, a pressure regulator can be added for smoother, more controlled liquid nitrogen transfer.

4. Easy Mobility for Multi-Tank Replenishment

The liquid nitrogen supply tank features built-in wheels and foot brakes, ensuring excellent mobility. This makes it ideal for frequent or multi-tank replenishment in laboratories or large facilities.

Смотрите товары и услуги рубрики Оборудование для лабораторий от других компаний России на портале RegTorg.Ru

|